Environmental Management

1. High Carbon Stock

Tropical natural forests hold large stores of carbon and greenhouse gases (GHG) are released when these forests are cleared. Given the substantial and continuing contribution that deforestation in tropical regions makes to the build-up of GHGs in the atmosphere, there is an inarguable need to reduce, minimise and eventually eliminate such deforestation.

No Development on High Carbon Stock (HCS) forests

Bukit Berlian Plantation has committed not to develop on HCS forests. This will be implemented through HCS assessments whose inputs will guide and support us in our land use planning. As a land-use planning tool, HCS assessments will integrate with High Conservation Value (HCV) assessments, peatland identification, and Free Prior and Informed Consent with local communities to propose a plan for a concession with areas for protection and areas that can potentially be developed.

As the HCS concept is relatively new to the palm oil industry, studies are still underway to identify HCS areas that can and should be protected, based on pragmatic assessments of social, economic and political factors that will affect the future viability of identified HCS patches.

In the interim and until an industry-wide methodology has been adopted, the definition of HCS forests adopted by Bukit Berlian Plantation will be in accordance with that in the HCS Approach Toolkit ( http://highcarbonstock.org ). We will not develop on High, Medium, Low and Young Regenerating Forests.

We will share more about the implementation progress of this policy in our progress reports.

2. High Conservation Value

Biodiversity conservation is a major part of responsible agriculture and landscape planning. Indonesia has a rich and immensely varied ecosystem and we recognise the importance of protecting the habitats of rare and endangered species as part of sustainable palm oil production. Our conservation priorities include forest sustainability, river bank integrity, water source preservation, soil health, ecosystem vitality, and species preservation.

No Development on High Conservation Value (HCV) areas

HCV areas are wildlife habitats, rare ecosystems and cultural areas found across land concessions for development and in our existing plantations. As part of our land use planning process, we undertake HCV assessments as well as Social and Environmental Impact Assessments (SEIA) for all our new development areas, in line with the New Planting Procedure (NPP) required by the RSPO. In the assessment, assessors evaluate habitat quality, soil conditions, peat presence, river quality, and community cultural identity. Identified HCV areas are to be conserved, maintained and not further developed into oil palm plantations. Signboards are placed at strategic spots to highlight HCV areas within our concessions. We have introduced HCV awareness programmes at a few of our estates to educate our workers and local communities about the importance of biodiversity conservation and to inform and guide them on the restrictions imposed on HCV areas. Rehabilitation is also conducted to restore degraded HCV areas back to their prior conditions. We plant multi-purpose tree species which carry economic value, such as Matoa (Pometia sp.) and Durian (Durio sp.).

We have a policy against hunting, injuring, possessing and killing of rare and endangered wildlife within our plantations. Any infringement of this policy will result in disciplinary measures, including termination of employment. We have also collaborated with local conservation agencies on the management of rare and endangered species and on educating local communities about the importance of protecting such species

3. Peat, Soil and Water Management

No Peat Development

Bukit Berlian Plantation has committed not to develop on peat areas regardless of depth. Peat soil is defined as soil with more than 65% organic matter.

For existing plantations on peat areas, we will implement best practices in the management of plantations on peat. We will ensure groundwater levels are between 50 centimetres and 75 centimetres deep to prevent subsidence and carbon dioxide emissions.

Soil Management

Bukit Berlian Plantation soil management practices are aimed at maintaining and enhancing soil fertility and reducing risks of soil degradation posed by our activities. Our objective is to enable our oil palms to attain their full productive potential, but through minimal use of inorganic fertilisers.

For new development areas, we mechanically clear land and harness the organic contents within fallen, decomposing biomass to replenish plantation soil. This provides a rich substrate for new plantings and reduces inorganic feriliser usage. On undulating plantations, we build terraces and silt pits to minimise soil erosion and the leaching of fertilisers and pesticides into water bodies. Buffer zones are maintained along riparian strips to protect river banks and maintain water quality.

Before the planting or during the immature phase of oil palms, our estates are planted with legume cover crops to conserve and improve soil fertility and fix atmospheric nitrogen for the trees.

We recycle all the biomass and organic by-products produced in our plantations and mills such as pruned fronds, EFB and POME and use them as organic fertilisers. This practice helps reduce the use of inorganic fertilisers. However, the use of such organic fertilisers alone is not sufficient to maximise the potential of the palms. Our research team therefore conducts site specific leaf and soil analysis to recommend the amount of inorganic fertiliser required to create a balanced nutrition programmme for our plantations.

Water Management

As an agribusiness, water is crucial not only for the maintenance of our crops but also in other areas of our operations such as the well-being of our workers and to generate steam for processing. We adopt best water management practices to ensure efficient use of water, to prevent pollution of waterways and to minimise disruption of water supply in our operations. Our efforts include:

Constructing trenches, drains and silt pits to ensure good drainage and prevent flooding during rainy season. These also serve water containment purposes to maintain soil moisture in the plantation during the dry season.

Spreading and stacking prune fronds according to land contours to reduce surface runoff and maximise water retention.

Preserving measured buffer zones along riparian river strip to protect river banks and to maintain water quality.

Constructing wells and dams in housing areas to ensure steady water supply for our employees as well as local communities.

Identifying and protecting water sources that are important for the local wildlife and surrounding communities by conducting HCV assessments prior to development.

Treating palm oil mill and refinery effluents to ensure the Biological Oxygen Demand (BOD) level and other indicators are within the legal limits before being discharged or used for land applications

4. Zero Burning Policy

Bukit Berlian Plantation observes a strict zero-burning policy in our land clearing and preparation process for all new developments as well as future replanting. Instead, we mechanically clear land in preparation for new plantings and harness the organic contents within fallen, decomposing biomass to replenish plantation soil. Our zero-burning policy is communicated to both employees and contractors and any non-compliance can result in termination of employment or contracts.

Fire Monitoring and Management

Our plantations are vulnerable to forest fires that can ignite due to extreme dry and hot weather, accidents, or deliberate slash and burn agriculture practices. These fires not only release air pollutants that a ffect air quality, but are also hazardous to our plantation assets and our workers. To safeguard our plantations against such fire risks, we have fire hazard monitoring and management processes in place. Measures include:

• Satellite monitoring

We detect and monitor hotspots by using satellite information and overlaying them with our plantation boundary maps. Ground verification is then conducted on satellite hotspots that appear within our plantation boundaries.

• Fire danger index

We have developed a fire danger index to help us assess fire risks. The index is determined by taking into account four important factors - humidity level, number of days without any rainfall, total rainfall in the past 15 days, and general condition of vegetation (grass) in the estate.

• Mapping of fire-prone areas

We map fire-prone areas in all of our plantations and the maps are regularly updated to ensure accuracy. Warning signages are placed near the fire-prone areas to alert and increase the awareness among our employees, contractors, and others who have access to these areas.

• Daily patrols and briefings

Our security personnel conduct daily patrols focusing on identified fire-prone areas, worker housing areas and areas adjacent to local villages. We also increase the frequency of patrols during dry seasons. In addition, all workers are reminded during their daily briefings to report any fires spotted within our plantations and its surrounding areas.

• Establishing watch towers

We establish watch towers within our plantations, where necessary, to improve fire detection.

• Maintaining a competent firefighting team

We maintain firefighting teams in all our plantations. These teams are equipped with up-to-date fire-fighting equipment and proper skills through regular trainings and fire drills.

Should a fire be detected within or near our plantations, the fire management team will be mobilised to extinguish the fire. Employees and villages nearby will be alerted and the evacuation protocol will be executed. Assistance from the local fire department will be sought if necessary. We document and report all incidents of fire within or near our plantations to the local authorities. Further investigations will also be carried out to determine the origin and cause of fire.

5. Greenhouses Gases

Greenhouse gases (GHG) associated with the greenhouse effect and subsequent global warming are cause by the accumulation of mostly carbon dioxide and other gases such as methane and nitrogen dioxide in the atmosphere. The prinicpal sources of GHG emissions in our operation areas :

• Carbon dioxide emissions arising from changes in carbon stock during the development of new plantations

• Methane emissions from Palm Oil Mill Effluent (POME) ponds

• Carbon dioxide emissions arising from the use of fuels by the palm oil mills, transportation and machinery

• Nitrous oxide emissions from fertilisers

Bukit Berlian Plantation have committed to no new planting on High Carbon Stock forest and on peatlands. These areas contain rich carbon stocks and are a significant source of GHG emissions if disturbed. We have committed to progressively reduce GHG emissions in our operations.

We have installed methane capture system at one of our palm oil mill where methane emissions generated by the POME is trapped and flared off so that it does not get released into the atmosphere. We are looking to extend similar methane capture facilities to more mills in our operations.

Most of the energy consumption in our plantations and palm oil mills come from renewable sources. Waste materials from our production, such as fibres and shell, are recycled and used as biomass fuel to generate power for our boilers. This helps to cut down our consumption of fossil fuels, by reducing our dependence on electricity from the national and local grids as well as diesel-fired plant generators

6. Integrated Pest Management

Integrated Pest Management is the practice of using a range of strategies to sustainably maintain pest populations within thresholds while causing minimal harm to local ecosystems. We adopt the IPM approach in managing pests in our plantations. Biological controls are introduced where possible, to reduce risks that could be caused by the release of chemicals into the ecosystem. We only use pesticides which are registered with and permitted by the Ministry of Agriculture.

Oil palm pests include rates, rhinoceros beetles, bunch moths, bagworms and nettle caterpillars. Barn owls are used in our plantations as a biological control agent for fresh fruit bunches (FFB) eating rat populations. We also plant crops such as the Cassia cobanensis, Antigonon Leptopus, Turnera subulata, Cordyceps entomopathogenic, and Carambola sp. These beneficial plants encourage parasites and attract predators of palm leaf-eating pests such as bagworms and caterpillars

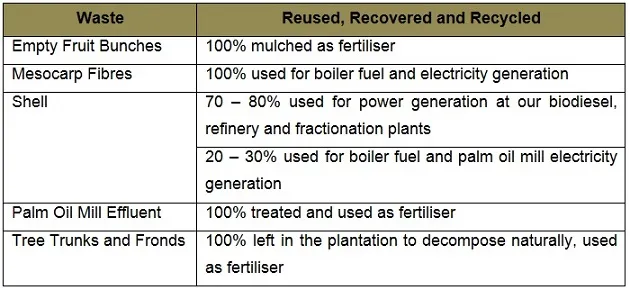

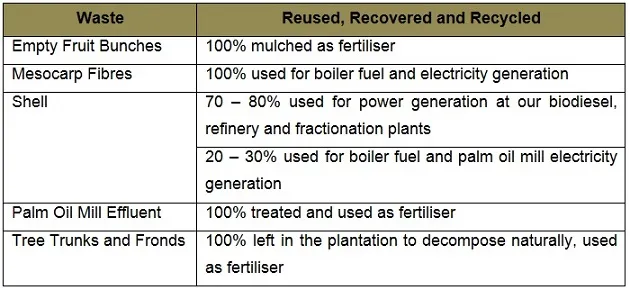

7. Waste Management

All organic plantation wastes and by-products from our milling activities are reused, recovered and recycled. Palm oil mill effluent (POME), empty fruit bunches (EFB), fibres and shells are the by-products of our crude palm oil (CPO) production.

Treated POME is collected, returned and reused in our plantations as organic fertiliser. POME is collected in anaerobic open ponds on our estates for treatment and POME parameters are monitored regularly to ensure their compliance with the government regulated limit for effluent land application. In addition to POME, EFB are also applied to land as organic fertiliser. EFB can be applied as mulch to conserve moisture, improve soil fertility, and reduce weed growth. Fibres and shells are used to generate power in our palm oil mills and refineries for our boiler.

We have an operational procedure covering hazardous waste handling activities including leakage handling. Hazardous waste streams include pesticide packaging, expired pesticides, used batteries, used lubricants and filters, empty paint cans and printer cartridges and needles from health clinics. All hazardous waste streams are segregated, labelled and stored within secure, fire resistant temporary storage facilities that are equipped with spillage containment kits, alarms, firefighting equipment and first aid kits. Facilities are inspected weekly and waste is collected by licensed third-party hazardous waste collectors. These procedures fulfill the international and national sustainability standard

Tropical natural forests hold large stores of carbon and greenhouse gases (GHG) are released when these forests are cleared. Given the substantial and continuing contribution that deforestation in tropical regions makes to the build-up of GHGs in the atmosphere, there is an inarguable need to reduce, minimise and eventually eliminate such deforestation.

No Development on High Carbon Stock (HCS) forests

Bukit Berlian Plantation has committed not to develop on HCS forests. This will be implemented through HCS assessments whose inputs will guide and support us in our land use planning. As a land-use planning tool, HCS assessments will integrate with High Conservation Value (HCV) assessments, peatland identification, and Free Prior and Informed Consent with local communities to propose a plan for a concession with areas for protection and areas that can potentially be developed.

As the HCS concept is relatively new to the palm oil industry, studies are still underway to identify HCS areas that can and should be protected, based on pragmatic assessments of social, economic and political factors that will affect the future viability of identified HCS patches.

In the interim and until an industry-wide methodology has been adopted, the definition of HCS forests adopted by Bukit Berlian Plantation will be in accordance with that in the HCS Approach Toolkit ( http://highcarbonstock.org ). We will not develop on High, Medium, Low and Young Regenerating Forests.

We will share more about the implementation progress of this policy in our progress reports.

2. High Conservation Value

Biodiversity conservation is a major part of responsible agriculture and landscape planning. Indonesia has a rich and immensely varied ecosystem and we recognise the importance of protecting the habitats of rare and endangered species as part of sustainable palm oil production. Our conservation priorities include forest sustainability, river bank integrity, water source preservation, soil health, ecosystem vitality, and species preservation.

No Development on High Conservation Value (HCV) areas

HCV areas are wildlife habitats, rare ecosystems and cultural areas found across land concessions for development and in our existing plantations. As part of our land use planning process, we undertake HCV assessments as well as Social and Environmental Impact Assessments (SEIA) for all our new development areas, in line with the New Planting Procedure (NPP) required by the RSPO. In the assessment, assessors evaluate habitat quality, soil conditions, peat presence, river quality, and community cultural identity. Identified HCV areas are to be conserved, maintained and not further developed into oil palm plantations. Signboards are placed at strategic spots to highlight HCV areas within our concessions. We have introduced HCV awareness programmes at a few of our estates to educate our workers and local communities about the importance of biodiversity conservation and to inform and guide them on the restrictions imposed on HCV areas. Rehabilitation is also conducted to restore degraded HCV areas back to their prior conditions. We plant multi-purpose tree species which carry economic value, such as Matoa (Pometia sp.) and Durian (Durio sp.).

We have a policy against hunting, injuring, possessing and killing of rare and endangered wildlife within our plantations. Any infringement of this policy will result in disciplinary measures, including termination of employment. We have also collaborated with local conservation agencies on the management of rare and endangered species and on educating local communities about the importance of protecting such species

3. Peat, Soil and Water Management

No Peat Development

Bukit Berlian Plantation has committed not to develop on peat areas regardless of depth. Peat soil is defined as soil with more than 65% organic matter.

For existing plantations on peat areas, we will implement best practices in the management of plantations on peat. We will ensure groundwater levels are between 50 centimetres and 75 centimetres deep to prevent subsidence and carbon dioxide emissions.

Soil Management

Bukit Berlian Plantation soil management practices are aimed at maintaining and enhancing soil fertility and reducing risks of soil degradation posed by our activities. Our objective is to enable our oil palms to attain their full productive potential, but through minimal use of inorganic fertilisers.

For new development areas, we mechanically clear land and harness the organic contents within fallen, decomposing biomass to replenish plantation soil. This provides a rich substrate for new plantings and reduces inorganic feriliser usage. On undulating plantations, we build terraces and silt pits to minimise soil erosion and the leaching of fertilisers and pesticides into water bodies. Buffer zones are maintained along riparian strips to protect river banks and maintain water quality.

Before the planting or during the immature phase of oil palms, our estates are planted with legume cover crops to conserve and improve soil fertility and fix atmospheric nitrogen for the trees.

We recycle all the biomass and organic by-products produced in our plantations and mills such as pruned fronds, EFB and POME and use them as organic fertilisers. This practice helps reduce the use of inorganic fertilisers. However, the use of such organic fertilisers alone is not sufficient to maximise the potential of the palms. Our research team therefore conducts site specific leaf and soil analysis to recommend the amount of inorganic fertiliser required to create a balanced nutrition programmme for our plantations.

Water Management

As an agribusiness, water is crucial not only for the maintenance of our crops but also in other areas of our operations such as the well-being of our workers and to generate steam for processing. We adopt best water management practices to ensure efficient use of water, to prevent pollution of waterways and to minimise disruption of water supply in our operations. Our efforts include:

Constructing trenches, drains and silt pits to ensure good drainage and prevent flooding during rainy season. These also serve water containment purposes to maintain soil moisture in the plantation during the dry season.

Spreading and stacking prune fronds according to land contours to reduce surface runoff and maximise water retention.

Preserving measured buffer zones along riparian river strip to protect river banks and to maintain water quality.

Constructing wells and dams in housing areas to ensure steady water supply for our employees as well as local communities.

Identifying and protecting water sources that are important for the local wildlife and surrounding communities by conducting HCV assessments prior to development.

Treating palm oil mill and refinery effluents to ensure the Biological Oxygen Demand (BOD) level and other indicators are within the legal limits before being discharged or used for land applications

4. Zero Burning Policy

Bukit Berlian Plantation observes a strict zero-burning policy in our land clearing and preparation process for all new developments as well as future replanting. Instead, we mechanically clear land in preparation for new plantings and harness the organic contents within fallen, decomposing biomass to replenish plantation soil. Our zero-burning policy is communicated to both employees and contractors and any non-compliance can result in termination of employment or contracts.

Fire Monitoring and Management

Our plantations are vulnerable to forest fires that can ignite due to extreme dry and hot weather, accidents, or deliberate slash and burn agriculture practices. These fires not only release air pollutants that a ffect air quality, but are also hazardous to our plantation assets and our workers. To safeguard our plantations against such fire risks, we have fire hazard monitoring and management processes in place. Measures include:

• Satellite monitoring

We detect and monitor hotspots by using satellite information and overlaying them with our plantation boundary maps. Ground verification is then conducted on satellite hotspots that appear within our plantation boundaries.

• Fire danger index

We have developed a fire danger index to help us assess fire risks. The index is determined by taking into account four important factors - humidity level, number of days without any rainfall, total rainfall in the past 15 days, and general condition of vegetation (grass) in the estate.

• Mapping of fire-prone areas

We map fire-prone areas in all of our plantations and the maps are regularly updated to ensure accuracy. Warning signages are placed near the fire-prone areas to alert and increase the awareness among our employees, contractors, and others who have access to these areas.

• Daily patrols and briefings

Our security personnel conduct daily patrols focusing on identified fire-prone areas, worker housing areas and areas adjacent to local villages. We also increase the frequency of patrols during dry seasons. In addition, all workers are reminded during their daily briefings to report any fires spotted within our plantations and its surrounding areas.

• Establishing watch towers

We establish watch towers within our plantations, where necessary, to improve fire detection.

• Maintaining a competent firefighting team

We maintain firefighting teams in all our plantations. These teams are equipped with up-to-date fire-fighting equipment and proper skills through regular trainings and fire drills.

Should a fire be detected within or near our plantations, the fire management team will be mobilised to extinguish the fire. Employees and villages nearby will be alerted and the evacuation protocol will be executed. Assistance from the local fire department will be sought if necessary. We document and report all incidents of fire within or near our plantations to the local authorities. Further investigations will also be carried out to determine the origin and cause of fire.

5. Greenhouses Gases

Greenhouse gases (GHG) associated with the greenhouse effect and subsequent global warming are cause by the accumulation of mostly carbon dioxide and other gases such as methane and nitrogen dioxide in the atmosphere. The prinicpal sources of GHG emissions in our operation areas :

• Carbon dioxide emissions arising from changes in carbon stock during the development of new plantations

• Methane emissions from Palm Oil Mill Effluent (POME) ponds

• Carbon dioxide emissions arising from the use of fuels by the palm oil mills, transportation and machinery

• Nitrous oxide emissions from fertilisers

Bukit Berlian Plantation have committed to no new planting on High Carbon Stock forest and on peatlands. These areas contain rich carbon stocks and are a significant source of GHG emissions if disturbed. We have committed to progressively reduce GHG emissions in our operations.

We have installed methane capture system at one of our palm oil mill where methane emissions generated by the POME is trapped and flared off so that it does not get released into the atmosphere. We are looking to extend similar methane capture facilities to more mills in our operations.

Most of the energy consumption in our plantations and palm oil mills come from renewable sources. Waste materials from our production, such as fibres and shell, are recycled and used as biomass fuel to generate power for our boilers. This helps to cut down our consumption of fossil fuels, by reducing our dependence on electricity from the national and local grids as well as diesel-fired plant generators

6. Integrated Pest Management

Integrated Pest Management is the practice of using a range of strategies to sustainably maintain pest populations within thresholds while causing minimal harm to local ecosystems. We adopt the IPM approach in managing pests in our plantations. Biological controls are introduced where possible, to reduce risks that could be caused by the release of chemicals into the ecosystem. We only use pesticides which are registered with and permitted by the Ministry of Agriculture.

Oil palm pests include rates, rhinoceros beetles, bunch moths, bagworms and nettle caterpillars. Barn owls are used in our plantations as a biological control agent for fresh fruit bunches (FFB) eating rat populations. We also plant crops such as the Cassia cobanensis, Antigonon Leptopus, Turnera subulata, Cordyceps entomopathogenic, and Carambola sp. These beneficial plants encourage parasites and attract predators of palm leaf-eating pests such as bagworms and caterpillars

7. Waste Management

All organic plantation wastes and by-products from our milling activities are reused, recovered and recycled. Palm oil mill effluent (POME), empty fruit bunches (EFB), fibres and shells are the by-products of our crude palm oil (CPO) production.

Treated POME is collected, returned and reused in our plantations as organic fertiliser. POME is collected in anaerobic open ponds on our estates for treatment and POME parameters are monitored regularly to ensure their compliance with the government regulated limit for effluent land application. In addition to POME, EFB are also applied to land as organic fertiliser. EFB can be applied as mulch to conserve moisture, improve soil fertility, and reduce weed growth. Fibres and shells are used to generate power in our palm oil mills and refineries for our boiler.

We have an operational procedure covering hazardous waste handling activities including leakage handling. Hazardous waste streams include pesticide packaging, expired pesticides, used batteries, used lubricants and filters, empty paint cans and printer cartridges and needles from health clinics. All hazardous waste streams are segregated, labelled and stored within secure, fire resistant temporary storage facilities that are equipped with spillage containment kits, alarms, firefighting equipment and first aid kits. Facilities are inspected weekly and waste is collected by licensed third-party hazardous waste collectors. These procedures fulfill the international and national sustainability standard